Concrete Pipe Gravity Flow Rate Calculator

Introduction to Concrete Pipes

Concrete pipes are widely used in construction and infrastructure projects due to their strength, durability, and cost-effectiveness. They are commonly used for drainage systems, culverts, sewer lines, and stormwater management. Below, we explore the properties, uses, and advantages of concrete pipes.

Properties of Concrete Pipes

- Durability: Concrete pipes are highly durable and can withstand harsh environmental conditions.

- Strength: They have high compressive strength, making them suitable for heavy loads.

- Corrosion Resistance: Concrete is resistant to chemical corrosion, making it ideal for sewer and wastewater systems.

- Fire Resistance: Concrete is non-combustible, providing excellent fire resistance.

- Low Thermal Conductivity: Concrete pipes provide good insulation against temperature changes.

Uses of Concrete Pipes

- Drainage Systems: Used in residential, commercial, and industrial drainage systems.

- Sewer Lines: Ideal for sewer and wastewater transportation due to their corrosion resistance.

- Culverts: Commonly used in road and railway construction for water passage.

- Stormwater Management: Effective in managing stormwater runoff in urban areas.

- Irrigation Systems: Used in agricultural irrigation for water distribution.

Advantages of Concrete Pipes

- Long Lifespan: Concrete pipes can last for decades with minimal maintenance.

- Cost-Effective: They are economical compared to other materials like metal or plastic.

- Eco-Friendly: Made from natural materials like cement, sand, and aggregates, making them environmentally friendly.

- High Load-Bearing Capacity: Suitable for heavy-duty applications such as road and railway culverts.

- Low Maintenance: Requires little to no maintenance over its lifespan.

Material Roughness Coefficients

| Material |

Roughness Coefficient |

| Cast Iron |

100 |

| Concrete |

110 |

| Copper |

140 |

| Plastic |

150 |

| Steel |

120 |

Velocity of Water Flow in a Pipe: An Example

Let’s use the pipe flow calculator to determine the velocity and discharge of a plastic pipe with a diameter of 0.6 feet. The pipe is 15 feet long, and the height difference between the beginning and endpoints is 6 feet.

Step-by-Step Calculation:

1. Calculate the Radius of the Pipe

Divide the diameter by 2 to find the radius:

\[ r = \frac{d}{2} = \frac{0.6}{2} = 0.3 \, \text{ft} \]

2. Find the Cross-Sectional Area of the Pipe

Use the formula for the area of a circle:

\[ A = \pi r^2 = \pi \times 0.3^2 \approx 0.2827 \, \text{ft}^2 \]

3. Determine the Perimeter of the Pipe

Calculate the perimeter using the formula:

\[ P = 2 \pi r = 2 \pi \times 0.3 \approx 1.885 \, \text{ft} \]

4. Calculate the Hydraulic Radius

Divide the area by the perimeter:

\[ R = \frac{A}{P} = \frac{0.2827}{1.885} \approx 0.15 \, \text{ft} \]

5. Select the Roughness Coefficient

Choose "Plastic" from the drop-down list, which has a roughness coefficient of:

\[ C = 150 \]

6. Calculate the Slope of the Pipe

Divide the height difference by the length of the pipe:

\[ S = \frac{y}{L} = \frac{6}{15} = 0.4 \]

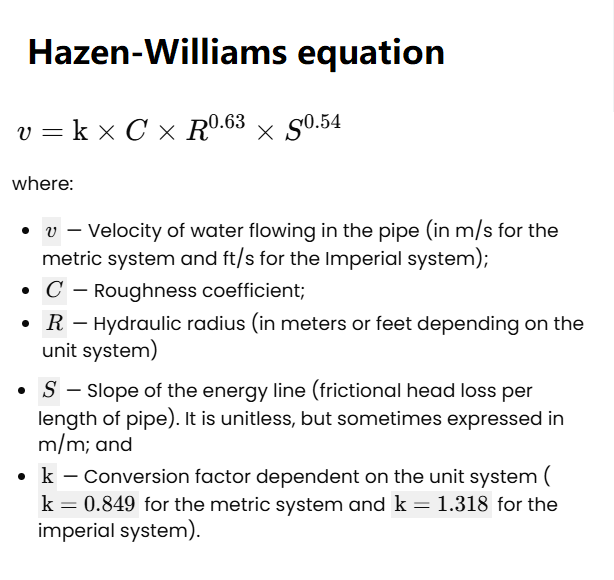

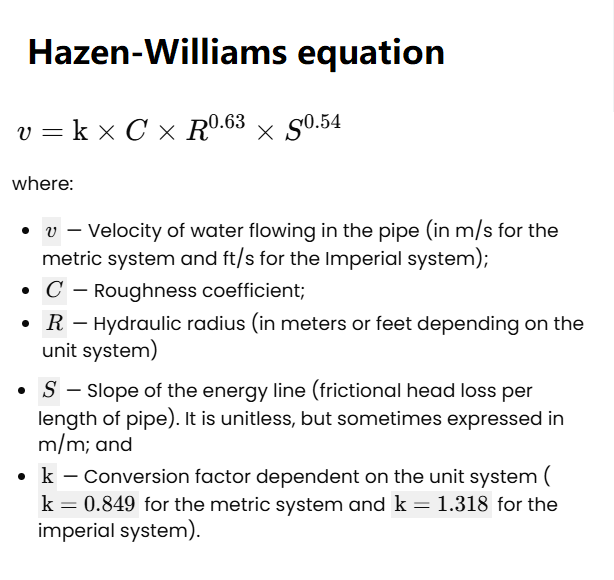

7. Use the Hazen-Williams Equation to Find Velocity

Apply the Hazen-Williams formula:

\[ v = 1.318 \times C \times R^{0.63} \times S^{0.54} \]

\[ v = 1.318 \times 150 \times 0.15^{0.63} \times 0.4^{0.54} \approx 36.48 \, \text{ft/s} \]

8. Calculate the Discharge

Multiply the velocity by the cross-sectional area:

\[ Q = A \times v = 0.2827 \times 34.56 \approx 10.31 \, \text{ft}^3/\text{s} \]

Flow Rate Calculator© - All Rights Reserved 2025