Copper Pipe Gravity Flow Rate Calculator

Introduction to Copper Pipes

Copper pipes are highly valued in the plumbing and construction industries due to their superior performance, versatility, and longevity. They are commonly used for water supply systems, heating, and refrigeration. Below, we explore the properties, uses, and advantages of copper pipes.

Properties of Copper Pipes

- Durability: Copper pipes are known for their long lifespan and ability to withstand corrosion, even in harsh conditions.

- Strength: They offer excellent strength, allowing them to withstand high pressure and stresses.

- Corrosion Resistance: Copper naturally resists corrosion, making it ideal for water supply and heating systems.

- Anti-Microbial Properties: Copper has inherent anti-microbial properties, preventing bacterial growth within the pipes.

- Thermal Conductivity: Copper pipes have high thermal conductivity, making them ideal for heating and cooling applications.

Uses of Copper Pipes

- Water Supply Systems: Widely used in plumbing systems for potable water due to their corrosion resistance and durability.

- Heating Systems: Commonly used in radiant heating and heating systems due to their excellent thermal conductivity.

- Refrigeration Systems: Essential in HVAC and refrigeration systems for transporting coolant.

- Gas Lines: Used in the transportation of natural gas or propane due to their ability to handle high-pressure conditions.

- Medical Gas Systems: Copper pipes are often used in hospitals and medical facilities for medical gas distribution.

Advantages of Copper Pipes

- Long Lifespan: Copper pipes can last for decades, often exceeding 50 years with proper maintenance.

- High Durability: Copper pipes are resistant to rust and corrosion, ensuring reliable performance over time.

- Health Benefits: The anti-microbial properties of copper make it a healthier choice for water distribution.

- Eco-Friendly: Copper is a recyclable material, making copper pipes an environmentally responsible choice.

- Ease of Installation: Copper pipes are easy to install and require minimal maintenance throughout their service life.

Material Roughness Coefficients

| Material |

Roughness Coefficient |

| Cast Iron |

100 |

| Concrete |

110 |

| Copper |

140 |

| Plastic |

150 |

| Steel |

120 |

Velocity of Water Flow in a Pipe: An Example

Let’s use the pipe flow calculator to determine the velocity and discharge of a plastic pipe with a diameter of 0.6 feet. The pipe is 15 feet long, and the height difference between the beginning and endpoints is 6 feet.

Step-by-Step Calculation:

1. Calculate the Radius of the Pipe

Divide the diameter by 2 to find the radius:

\[ r = \frac{d}{2} = \frac{0.6}{2} = 0.3 \, \text{ft} \]

2. Find the Cross-Sectional Area of the Pipe

Use the formula for the area of a circle:

\[ A = \pi r^2 = \pi \times 0.3^2 \approx 0.2827 \, \text{ft}^2 \]

3. Determine the Perimeter of the Pipe

Calculate the perimeter using the formula:

\[ P = 2 \pi r = 2 \pi \times 0.3 \approx 1.885 \, \text{ft} \]

4. Calculate the Hydraulic Radius

Divide the area by the perimeter:

\[ R = \frac{A}{P} = \frac{0.2827}{1.885} \approx 0.15 \, \text{ft} \]

5. Select the Roughness Coefficient

Choose "Plastic" from the drop-down list, which has a roughness coefficient of:

\[ C = 150 \]

6. Calculate the Slope of the Pipe

Divide the height difference by the length of the pipe:

\[ S = \frac{y}{L} = \frac{6}{15} = 0.4 \]

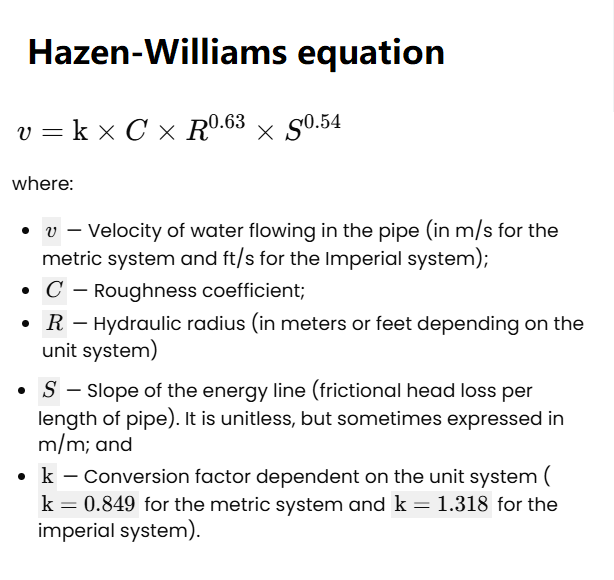

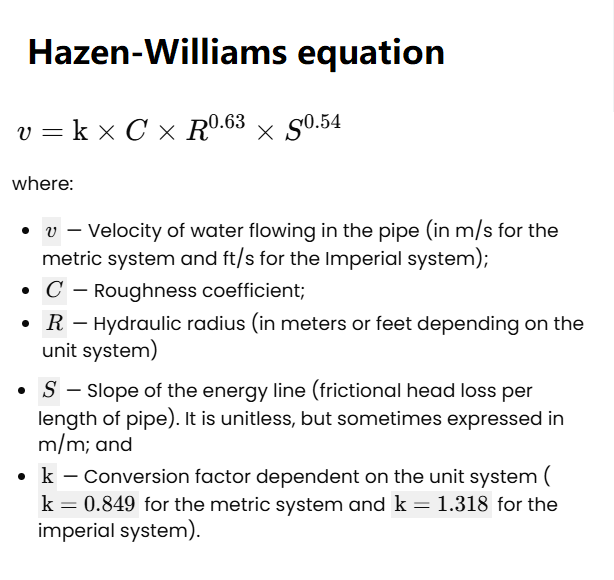

7. Use the Hazen-Williams Equation to Find Velocity

Apply the Hazen-Williams formula:

\[ v = 1.318 \times C \times R^{0.63} \times S^{0.54} \]

\[ v = 1.318 \times 150 \times 0.15^{0.63} \times 0.4^{0.54} \approx 36.48 \, \text{ft/s} \]

8. Calculate the Discharge

Multiply the velocity by the cross-sectional area:

\[ Q = A \times v = 0.2827 \times 34.56 \approx 10.31 \, \text{ft}^3/\text{s} \]

Flow Rate Calculator© - All Rights Reserved 2025