Steel Pipe Gravity Flow Rate Calculator

Introduction to Steel Pipes

Steel pipes are widely used in various industries due to their high strength, durability, and versatility. They are commonly used in water supply systems, oil and gas pipelines, construction, and industrial applications. Below, we explore the properties, uses, and advantages of steel pipes.

Properties of Steel Pipes

- High Strength: Steel pipes have excellent tensile and compressive strength, making them ideal for high-pressure applications.

- Corrosion Resistance: With coatings and treatments, steel pipes can resist rust and corrosion.

- Durability: Steel pipes are highly durable and can withstand extreme temperatures and pressures.

- Flexibility: Unlike brittle materials, steel pipes can handle stress and bending without breaking.

- Recyclability: Steel is a sustainable material and can be fully recycled, reducing environmental impact.

Uses of Steel Pipes

- Water Supply Systems: Used for transporting potable water in municipal and industrial settings.

- Oil and Gas Pipelines: Essential for transporting crude oil, natural gas, and petroleum products.

- Construction: Used in structural applications such as bridges, buildings, and scaffolding.

- HVAC Systems: Commonly used in heating, ventilation, and air conditioning systems.

- Mechanical and Industrial Applications: Found in manufacturing industries for machinery and equipment.

Advantages of Steel Pipes

- Longevity: Steel pipes have a long lifespan, especially when properly maintained.

- High Pressure Resistance: Suitable for high-pressure applications in oil, gas, and water distribution.

- Cost-Effective: Offers a balance between cost and durability, making it a preferred choice in many industries.

- Versatility: Can be manufactured in different thicknesses and diameters to suit various applications.

- Easy Fabrication: Can be welded, bent, or cut into different shapes, making it adaptable for diverse projects.

Material Roughness Coefficients

| Material |

Roughness Coefficient |

| Cast Iron |

100 |

| Concrete |

110 |

| Copper |

140 |

| Plastic |

150 |

| Steel |

120 |

Velocity of Water Flow in a Pipe: An Example

Let’s use the pipe flow calculator to determine the velocity and discharge of a plastic pipe with a diameter of 0.6 feet. The pipe is 15 feet long, and the height difference between the beginning and endpoints is 6 feet.

Step-by-Step Calculation:

1. Calculate the Radius of the Pipe

Divide the diameter by 2 to find the radius:

\[ r = \frac{d}{2} = \frac{0.6}{2} = 0.3 \, \text{ft} \]

2. Find the Cross-Sectional Area of the Pipe

Use the formula for the area of a circle:

\[ A = \pi r^2 = \pi \times 0.3^2 \approx 0.2827 \, \text{ft}^2 \]

3. Determine the Perimeter of the Pipe

Calculate the perimeter using the formula:

\[ P = 2 \pi r = 2 \pi \times 0.3 \approx 1.885 \, \text{ft} \]

4. Calculate the Hydraulic Radius

Divide the area by the perimeter:

\[ R = \frac{A}{P} = \frac{0.2827}{1.885} \approx 0.15 \, \text{ft} \]

5. Select the Roughness Coefficient

Choose "Plastic" from the drop-down list, which has a roughness coefficient of:

\[ C = 150 \]

6. Calculate the Slope of the Pipe

Divide the height difference by the length of the pipe:

\[ S = \frac{y}{L} = \frac{6}{15} = 0.4 \]

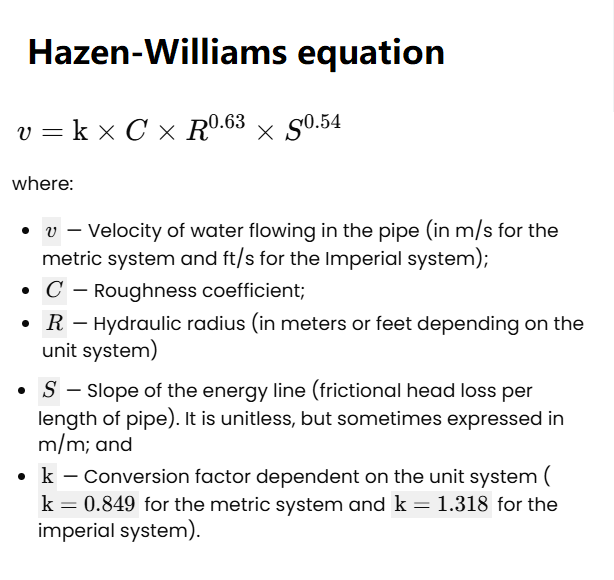

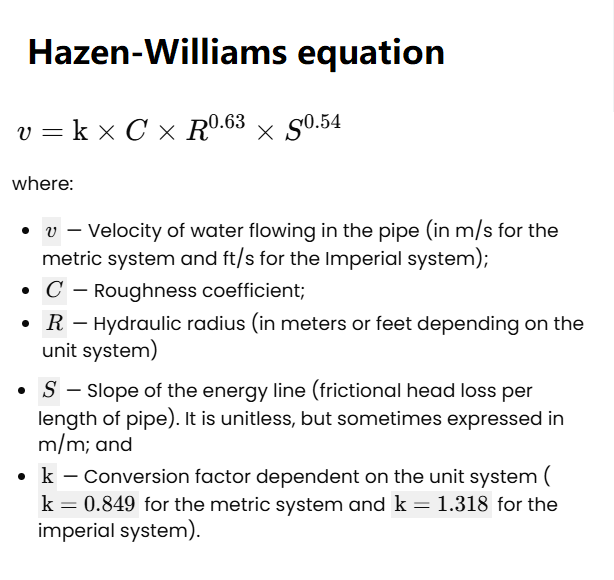

7. Use the Hazen-Williams Equation to Find Velocity

Apply the Hazen-Williams formula:

\[ v = 1.318 \times C \times R^{0.63} \times S^{0.54} \]

\[ v = 1.318 \times 150 \times 0.15^{0.63} \times 0.4^{0.54} \approx 36.48 \, \text{ft/s} \]

8. Calculate the Discharge

Multiply the velocity by the cross-sectional area:

\[ Q = A \times v = 0.2827 \times 34.56 \approx 10.31 \, \text{ft}^3/\text{s} \]

Flow Rate Calculator© - All Rights Reserved 2025